The selection of the correct battery is a very crucial factor in the success of any electronic project. Lithium Polymer (LiPo) batteries are very even more compact and have higher energy density and have become common among electronic designs. When choosing 3.7V LiPo battery to handle your PCB, some factors should be observed that would enable maximum battery performance and safety. This handbook will help you make important decisions like the loading requirements, the size of the box and the type connector to enable you make the best battery choice as part of your design.

Analyzing Load Requirements and Drain Characteristics

The power requirements of your PCB scheme must then be identified before picking a LiPo battery. Start with examining the operating load of your machine. This entails the computation of both the current load in normal operation and peaks. The knowledge of such requirements will enable you to select a battery that has the capacity to provide sufficient power in the usage of the device.

LiPo batteries have certain discharge ratings, which are commonly rendered as C-ratings. A battery C-rating defines the maximum discharge rate at which it can be discharged without being damaged. As an example, a 1000mAh battery of the 20C rating may provide a constant current of 20 000mA. There may be cases where your battery will reduce the available current due to a voltage sag. If the current demands of your device are greater than the peak current limits of your battery, you can avoid this problem by selecting a battery with equal to or greater peak current limits than what is required by your device.

Also think about the expectations in terms of the run time demands of your project. Different applications will demand different needs of battery capacity in sustaining an operation over a particular period. A larger battery capacity would be needed, in case your device is operated during long intervals. Yet, the trade-offs between the capacity and size/weight limitation constraints are an important part of the design step.

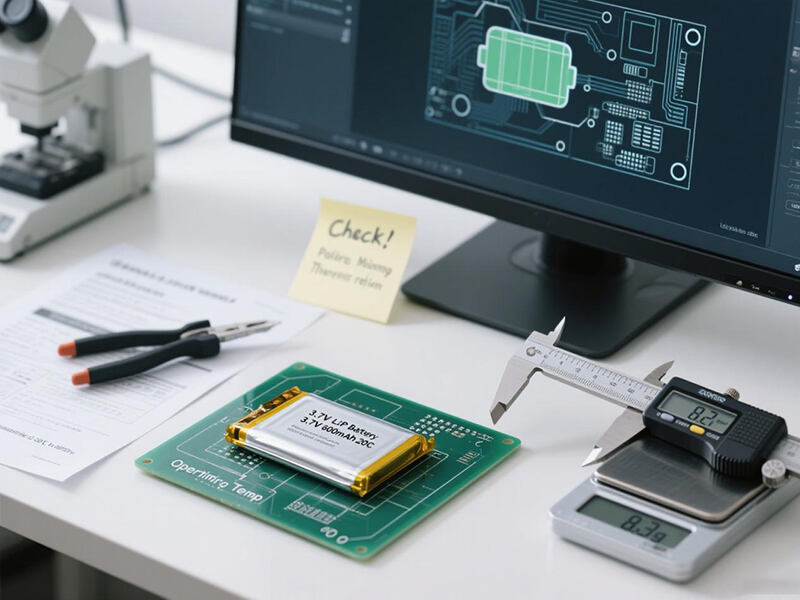

Matching Physical Dimensions and Connector Types

The other important aspect in LiPo battery selection is that it fits physically into your printed circuit board design. LiPo batteries are available in many shapes and sizes, so beware, that the canister fits the available space of your device. Determine the size precisely to prevent mechanical contacts, which may generate operation problem or result in deterioration of the battery and equipment.

Take into account the design of your PCB and any mechanical limitation such as the enclosure or other parts. An oversized, or poorly positioned battery may cause issues during assembly and use. In case of limited designs by size you may have to consider high-energy density storage batteries, or even re-designing, to fit energy requirements.

Types of Connectors are also determinative LiPo batteries have a variety of connectors like; JST, Molex or custom connectors. The most important part is to choose connector type that would fit in your design of a PCB. Connector selection misalignment may lead to inefficiency in power delivery or the necessity to use extra components such as adapters or made-to-order cables, thus complicating either the design or assembly of the product.

Also look at how easy or difficult it is to assemble and disassemble especially when your design has to have the batteries exchanged regularly or due to maintenance. The connector type of a battery should be simple to connect and disconnect in order to streamline the processes and minimize the chances of damage when handling.

Additional Considerations

Initial load requirements and physical dimensions are the major factors, but others can affect the choice of a 3.7V LiPo battery. These include:

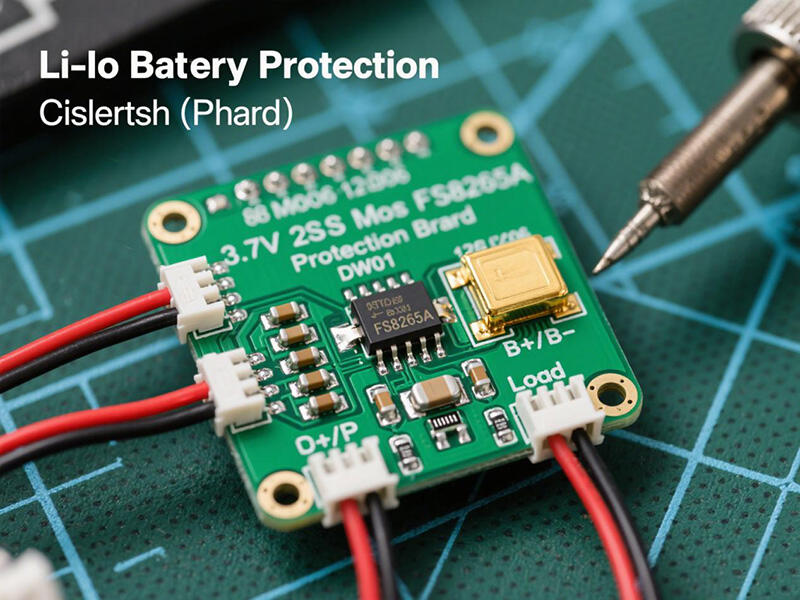

Safety Features: Batteries should have in-built safety measures like overcharging and undercharging so as to avoid scorched and fried batteries, which will eventually make the battery malfunction.

Cost: Find the balance in the budgeting of your project (considering quality and reliability of the battery). Using cheaper and lower quality batteries can initially be economical; however, it will pose premature battery failures and/or safety risks.

Environmental Conditions: Look at what the environment your device will be operating in will be like. Very high/ low temperatures are known to chill batteries and reduce battery life, therefore, it is essential to select a battery, which is ideal in terms of environmental conditions that will include extreme temperature.

Manufacturer Reputation: The manufacturer should have a good reputation and track record of repairing quality products. This is able to minimize the risks of bad quality batteries and achieve uniform performance.

To double up on it, choosing the appropriate 3.7V LiPo battery to feather your PCB design would be an in-depth consideration of power demands, size and fit of the component in relation to adjacent parts and pieces. When you are certain that such aspects are evaluated well, you can rest assured that the requirements that your device has to meet will be fulfilled successfully and without concessions.