As the world of technology is changing and evolving with new advances at a rapid pace, the need of lithium polymer (LiPo) batteries is growing day-by-day because of its presence in most aspects, be it a consumer electronic or even an industrial map. Such increase requires re-assessment of the packaging process to guarantee safe delivery of these super-intense batteries, especially at the wholesaler level. The LiPo battery logistics industry is currently experiencing a leap in innovative solutions that will enhance its safety & compliance. This paper will discuss some of the new trends of wholesale LiPo battery packaging.

Flame-Retardant Materials in Bulk LiPo Battery Packaging for Logistics Compliance

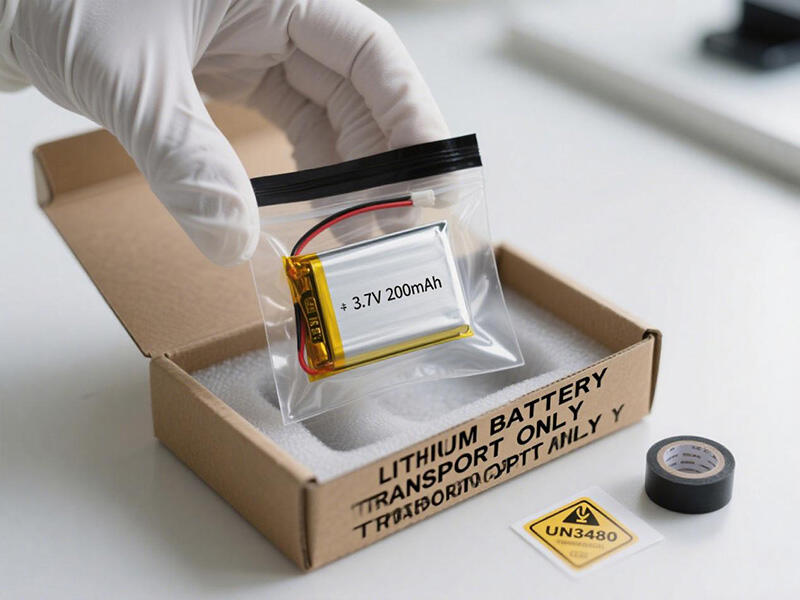

A critical issue in the transportation of LiPo batteries is that they can catch fire which has caused the establishment of strict safety measures and protocols on transporting LiPo throughout the world. To overcome such challenges, the use of flame-retardant materials is finding its way into the protective packaging solutions made by manufacturers. These materials reduce the risk of ignition and are able to contain any potential fire substantially reducing the risk of bulk transportation of LiPo batteries.

New developments are the use of more advanced polymer and composite materials that have better thermal resistance and fire resistance. When these elements are incorporated into their battery packaging, producers are able to maintain the safety of their logistic processes and comply with shipping regulations set at the international level. Another example is materials that have flame-resistance barrier properties like the intumescent coatings that swell when they get hot offer protection by blocking flames.

Besides, flame-retardant materials are increasingly becoming part of the design of the same battery packaging solutions due to both regulatory safety requirements and the level of commitment of the industry to safety. This will remain as trend since companies will focus more on safe and effective transportation of LiPo batteries to different parts of the supply chains which are becoming much more complicated.

Smart Labeling Innovations for Tracking Wholesale LiPo Battery Storage Conditions

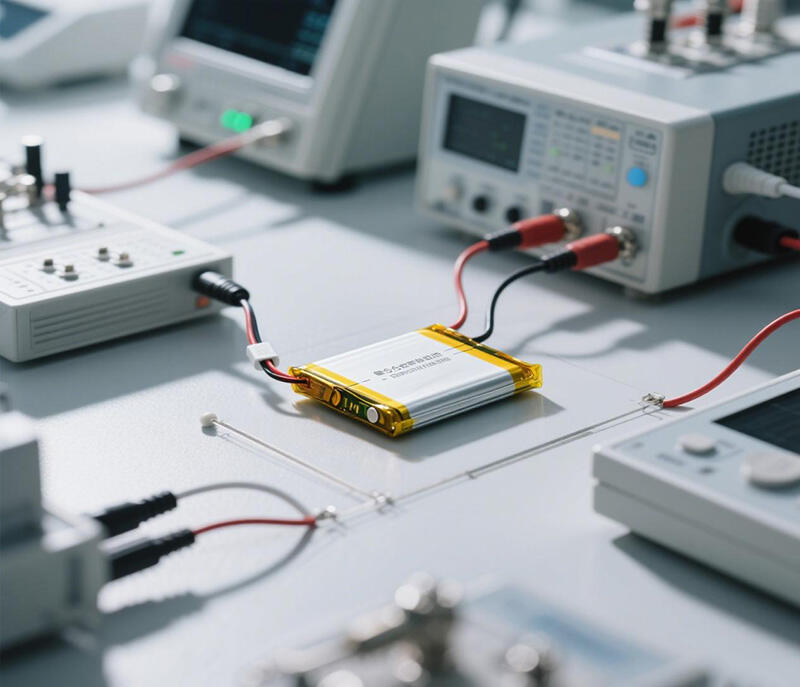

Smart technologies that are implemented in the packaging of the LiPo batteries is another major trend transforming the industry. One field that has attracted specific interest is the creation of intelligent labeling systems to be used as a way to monitor and trace storage conditions of batteries in transit and storage.

Such smart labels have sensors and RFID technology built-in, and they deliver real-time information on several environmental variables to include the temperature, humidity, and physical impact. This information is of paramount importance to keeping stored conditions optimal and to the safety and longevity of the batteries. With the help of IoT technologies, such labels may also provide alerts in case the conditions cease to be correspondent to predetermined parametres and enable urgent corrective measures to be implemented.

Also, smart labeling can increase tracking and management of inventory during supply chain. Automating the process of tracking would eliminate human error and enhance the efficiency of the logistics process of the company. In addition to enhancing safety, this technological innovation can yield a gold mine of insights that can lead to data-driven decision-making.

Smart labeling innovations are going to continue to increase in adoption as firms seek to efficiently streamline their supply chains and conform to the changing regulations. Consequently, these solutions are fast becoming an essential packaging step of today LiPo batteries.

The Future of LiPo Battery Packaging

Increasing demand LiPo batteries demands the packaging sector to find viable means of addressing the challenge of safe transportation. The identified trends represent a reorientation towards more advanced technologies that are both safety conscious and more sophisticated as enabled by concepts such as smart material science and smart technology.

Going forward, the extent of integrating these innovations would be likely to increase further since regulatory frameworks are also likely to be changing, and the industry is also trying to reduce the risks by transporting batteries. Specifically, the progressive research in the field of greener flame-retardant products and the perfection of smart labelling technology are sure to further improve the security and productivity of wholesale LiPo battery transportation.

In summary, safety, compliance, and innovation are on an active interplay in terms of the latest trends in LiPo battery packaging. Adoption of the new advancements enable companies not only to protect their products but also to align their operations to existing industry trend and consumer demands.